Assembly Automation

Assembly Automation solutions provided by Ming Automation Technology are designed to streamline your manufacturing processes, increase productivity, and ensure the highest quality standards. Our tailored assembly automation systems cater to various industries, delivering precise, reliable, and efficient solutions that meet your specific production requirements.

Custom Assembly Systems

Our customized assembly systems are designed to address your unique assembly needs, ensuring seamless integration with your existing operations. From small-scale assembly lines to complex, multi-stage processes, we provide solutions that enhance efficiency and reduce operational costs.

- Modular Design: Our systems feature a modular design that allows for easy customization and scalability, accommodating changes in production requirements.

- Precision Engineering: We use advanced engineering techniques to create systems that deliver accurate and consistent results, ensuring the highest quality standards.

- Seamless Integration: Our assembly systems are designed to integrate smoothly with your current production lines, minimizing disruption and maximizing productivity.

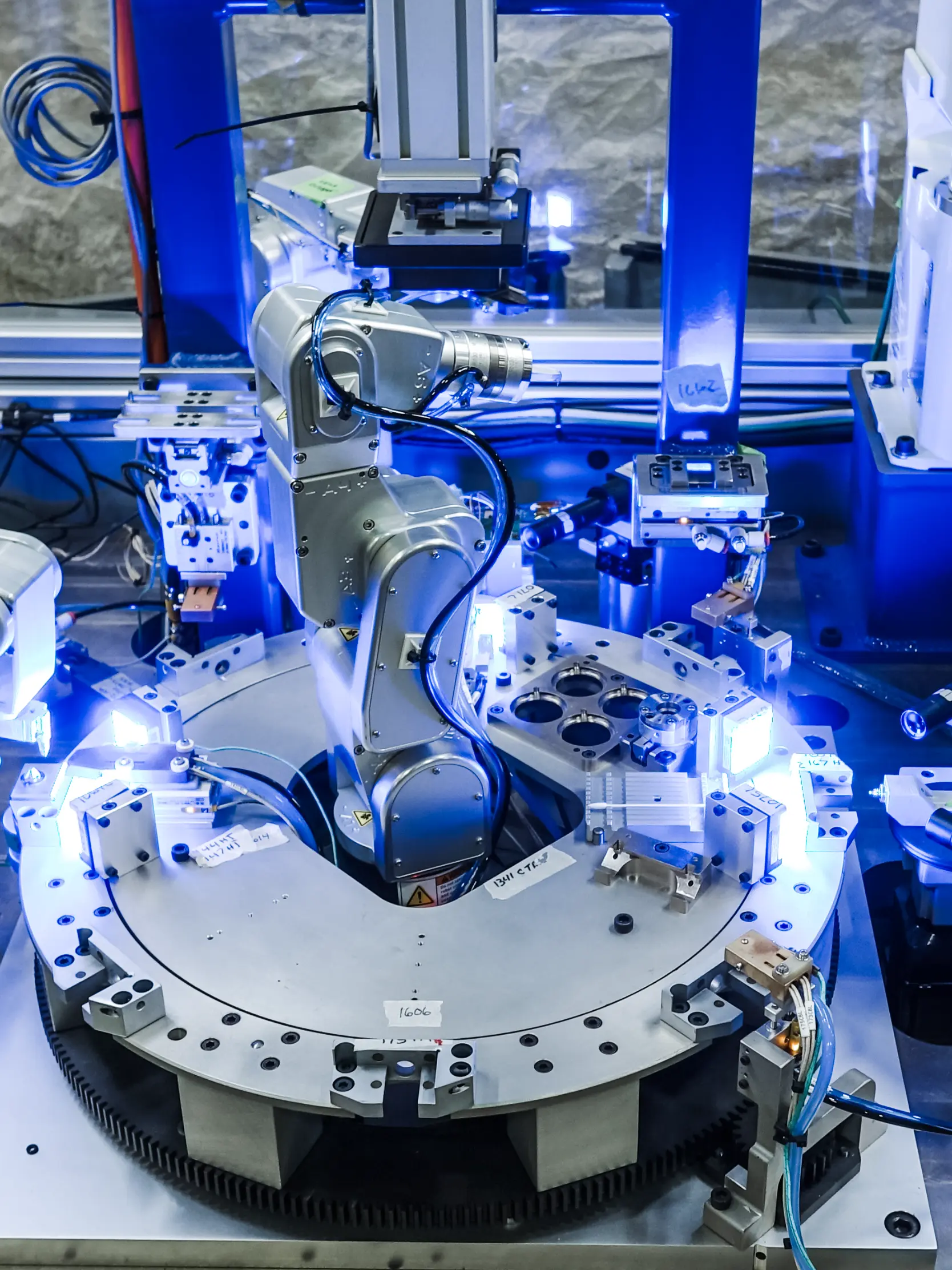

Robotic Assembly

Incorporating robotics into your assembly processes can significantly enhance efficiency, accuracy, and flexibility. Our robotic assembly solutions are tailored to meet the specific demands of your production environment.

- Versatility: Our robotic systems can handle a wide range of tasks, from simple assembly operations to complex, multi-step processes.

- Advanced Technology: We use the latest robotic technologies to ensure high precision, speed, and reliability in your assembly operations.

- Increased Efficiency: Robotic assembly systems can operate continuously, reducing downtime and increasing overall production throughput.

Automated Inspection

Quality control is a critical aspect of any assembly process. Our automated inspection systems ensure that every component and finished product meets your stringent quality standards.

- High Accuracy: Our inspection systems use advanced imaging and sensing technologies to detect even the smallest defects.

- Real-Time Monitoring: Automated inspection provides real-time data on product quality, enabling immediate corrective actions and reducing waste.

- Comprehensive Reporting: Our systems generate detailed reports, providing valuable insights into your production process and helping to identify areas for improvement.

<<Automotive Valve Leak Inspection

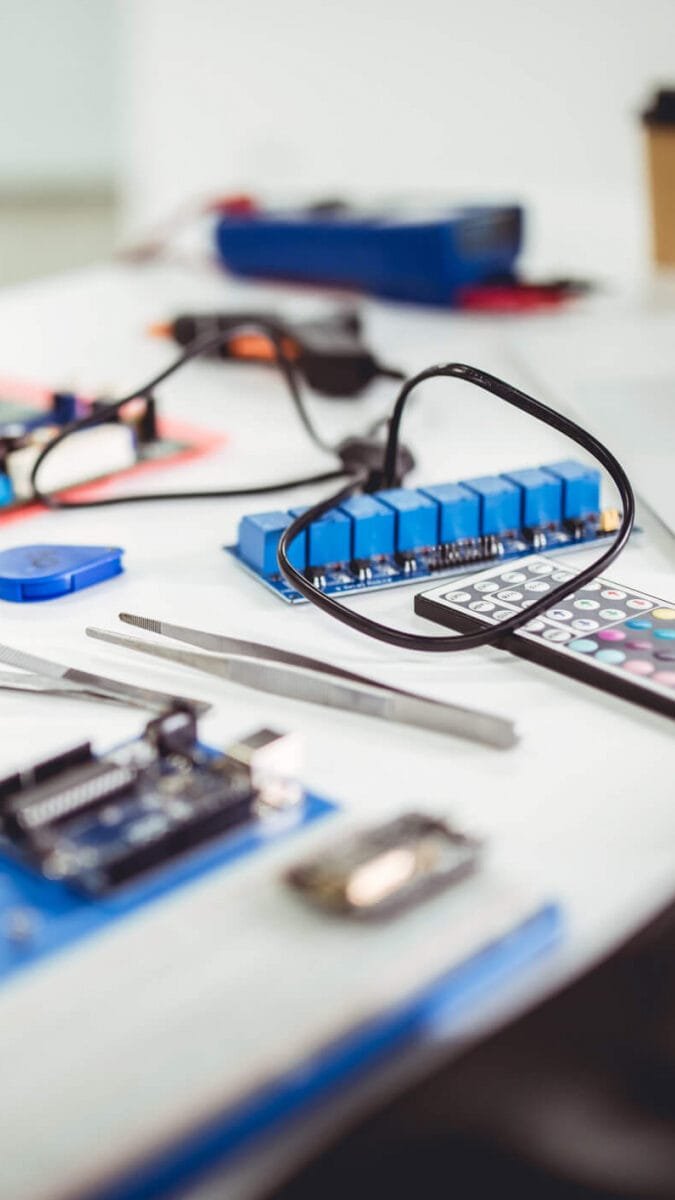

Custom Automation Components

In addition to complete assembly systems, we offer custom automation components that enhance the performance and efficiency of your existing equipment.

- Sensors and Actuators: Our high-quality sensors and actuators ensure precise control and operation of your assembly processes.

- Control Systems: We provide advanced control systems that offer robust performance, flexibility, and easy integration with your current infrastructure.

- Software Solutions: Our custom software solutions enable efficient management and optimization of your assembly operations, providing real-time data and analytics.

Why Choose Ming Automation Technology

- Expertise: With extensive experience in assembly automation, our team has the knowledge and skills to deliver exceptional solutions.

- Innovation: We are committed to incorporating the latest technologies and methodologies into our designs, ensuring top-tier performance.

- Quality: Our dedication to quality is evident in every aspect of our work, from design and manufacturing to installation and support.

- Customer Focus: We work closely with you to develop solutions that address your specific challenges and goals, ensuring complete satisfaction.

- Comprehensive Support: Our relationship with you doesn’t end with the delivery of your assembly system. We offer ongoing support, maintenance, and upgrades to ensure your systems continue to perform at their best.

Contact Us

Ready to revolutionize your assembly processes with our advanced automation solutions? Contact Ming Automation Technology today to discuss your specific needs and discover how our innovative systems can help you achieve your production goals.

Contact us today to discuss the requirements for your custom automation solutions.