Introduction to Automation Solutions

Automation solutions refer to the systematic use of technology and processes to perform tasks with minimal human intervention. These solutions have become integral to various industries, including manufacturing, automotive, and other sectors. In today’s fast-paced business environment, the need for efficiency and reliability has driven companies to adopt automation direct methodologies that streamline operations and enhance productivity. At Ming Automation Technology (Ming AutoTek), we specialize in providing tailored automation solutions that meet the unique needs of our clients, particularly in the automotive sector.

The importance of automation solutions cannot be understated. By automating repetitive and time-consuming tasks, businesses can achieve higher efficiency levels and focus their workforce on more strategic initiatives. For instance, in manufacturing, the implementation of industrial automation solutions can result in faster production cycles and greater output, which ultimately translates to a competitive edge in the marketplace. Moreover, automotive automation solutions have revolutionized vehicle production, leading to safer and more efficient manufacturing processes.

One of the critical benefits of automation is the reduction of human error. Automated systems operate consistently and accurately, minimizing the risk of mistakes that can arise from manual processes. This reliability is particularly crucial in sectors that demand high precision, such as healthcare and automotive manufacturing. Additionally, the process of automation solutions often leads to significant cost savings. By decreasing labor costs and minimizing errors, businesses can improve their bottom line and allocate resources more effectively.

Overall, automation solutions serve as a catalyst for transformation in the modern workforce. As technology continues to evolve, embracing these solutions will be essential for organizations aiming to remain competitive and responsive to market demands. Consequently, understanding the wide-ranging applications of automation, from automation direct to tailored industry-specific solutions, is vital for companies seeking sustainable growth and innovation.

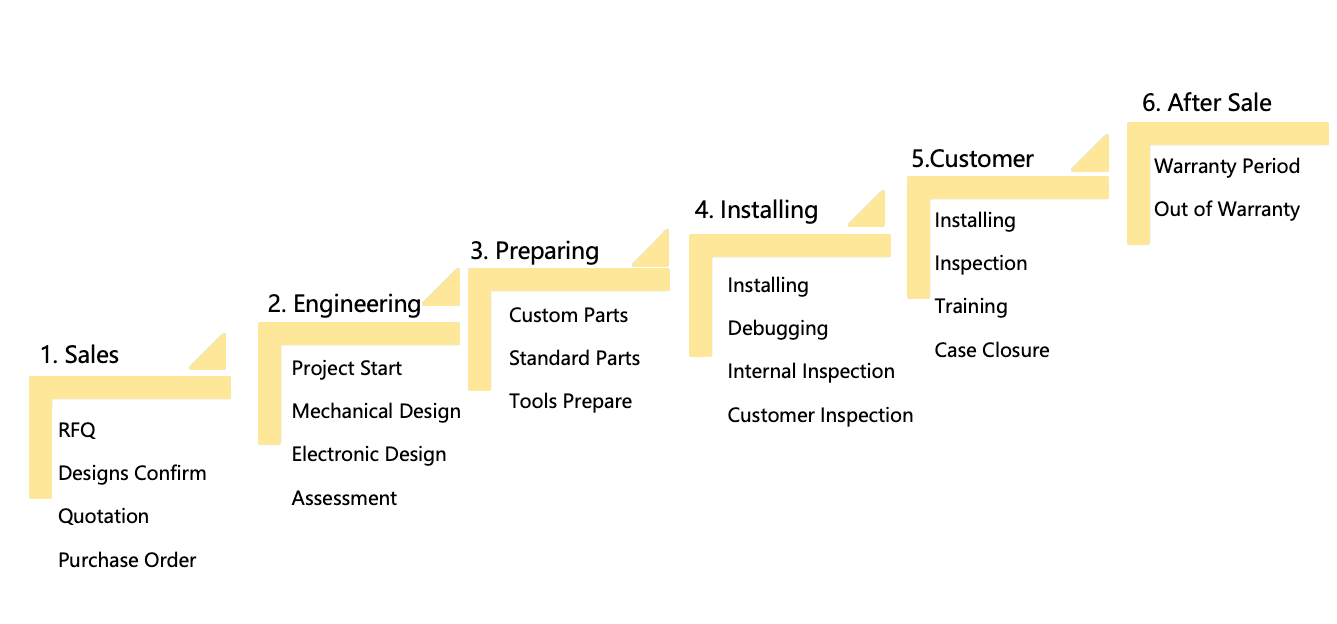

The Automation Solution Order Process

Custom Automation Solution Ordering Process

The implementation of automation solutions is a structured process that necessitates careful planning and execution to ensure alignment with organizational objectives. The initial step in this process involves identifying the need for automation within the specific context of the business. Organizations must evaluate their pain points and determine which workflows could benefit from increased efficiency, accuracy, or productivity. This phase is critical as it set the foundation for subsequent actions.

Once the need for automation is established, the next step is to assess existing workflows. This involves analyzing current processes to identify redundancies, bottlenecks, and areas where automation can provide significant improvements. Engaging stakeholders during this phase maximizes insights, as their expertise can highlight opportunities that may otherwise be overlooked. This assessment phase should also consider the current technology set, including any existing industrial automation solutions that may be integrated into the new system.

After completing the assessment, the design of the automation system can commence. This process entails outlining the specifications for the automation solutions, including the selection of appropriate technologies and methodologies. Careful consideration should be given to how these technologies will interact with existing systems, ensuring compatibility and minimizing disruptions. Furthermore, teams should focus on delineating clear objectives and success metrics to evaluate the effectiveness of the implemented solutions.

Testing the automation solution is a vital phase before deployment. This step allows businesses to validate the system’s functionality, addressing any issues that arise and ensuring that the automation operates as intended. Finally, the deployment phase involves integrating the automated system into daily operations, requiring ongoing monitoring and adjustments to align with evolving business goals. Adopting a systematic approach throughout the process of automation solutions aids in realizing the full potential of automation while enhancing operational efficiency.

The Role of Automation in the Automotive Industry

Automation has revolutionized the Automotive Industry, enhancing efficiency and productivity while ensuring high levels of precision and quality in manufacturing processes.

One of the most significant areas where automation direct is applied is in the production line, where automated assembly systems streamline various tasks. These systems allow manufacturers to reduce production times and minimize human error, resulting in faster turnaround and improved output consistency. The implementation of automation solutions has transformed traditional assembly lines into highly efficient systems capable of producing vehicles more rapidly while maintaining safety standards.

Robotics play a crucial role in automotive manufacturing, where they perform various tasks such as welding, painting, and material handling. These industrial automation solutions have elevated the quality of production by providing a level of accuracy that is difficult for human workers to achieve consistently. Furthermore, the integration of robotics allows for continuous operation, which enhances productivity. This shift towards robotic automation also alleviates the need for labor-intensive tasks, allowing human workers to focus on more complex functions that require cognitive skills, ultimately leading to a more skilled workforce.

Quality control measures have also evolved thanks to automation. Automated inspection systems are now a standard practice in automotive manufacturing, ensuring that each vehicle meets strict quality and safety standards. These systems utilize advanced sensors and imaging technology to identify defects or irregularities that may go unnoticed in manual inspections. By incorporating automation solutions from Emerson and others, manufacturers can further enhance their quality assurance processes, significantly reducing the probability of recalls and warranty claims. The process of automation solutions in quality control not only boosts efficiency but also elevates overall consumer satisfaction, cementing the automotive industry’s reputation for excellence.

Custom Automation Welding Equipment

The integration of automation in welding processes is becoming increasingly vital as industries aim to enhance productivity and maintain quality standards. Custom Automation Welding Equipment is designed to meet specific production requirements, allowing businesses to optimize their manufacturing processes thoroughly. This level of customization is essential for addressing the diverse challenges encountered in various production environments.

There are several types of welding processes that can benefit from automation solutions. For instance, robotic arc welding, laser welding, and spot welding are among the most commonly utilized automated techniques. Each of these methods presents distinct advantages over traditional manual welding. Robotic arc welding, for example, allows for consistent, high-speed welding, minimizing the likelihood of defects and increasing throughput. The precision of robotic systems significantly enhances the quality of welds, resulting in improved product durability.

Furthermore, the implementation of automated welding solutions often leads to better resource management. By reducing the reliance on manual labor, companies can allocate human resources towards more strategic tasks, thereby enhancing workforce efficiency. Also, automation direct offers advanced technologies that ensure repeatability and accuracy in welding operations. This is particularly beneficial in industries such as automotive, where high-volume production cycles require strict adherence to quality standards.

In addition to improving production efficiency, custom automation welding equipment can also facilitate a safer working environment. Elevated safety measures can be implemented through automation, minimizing human error and the associated risks. Companies that adopt industrial automation solutions not only enhance their competitiveness but also contribute to sustainability by optimizing energy consumption and reducing waste during the welding process.

Overall, the process of automation solutions in welding is crucial for adapting to the ever-evolving demands of manufacturing. By investing in tailored automated welding systems, companies can achieve significant improvements in their operational efficiency and product quality.

Custom Testing Equipment in Automation

In the realm of industrial automation solutions, Custom Testing Equipment plays a pivotal role in ensuring quality assurance and regulatory compliance across various manufacturing sectors. These specialized tools are designed to meet the distinct requirements of specific processes and products, thereby enhancing the overall efficiency of production lines. Automated testing solutions are instrumental in identifying defects and ensuring that manufactured products adhere to industry standards.

One of the key benefits of utilizing custom testing equipment is its ability to streamline the testing phase within the process of automation solutions. For example, automated optical inspection (AOI) systems are employed in electronics manufacturing to inspect printed circuit boards (PCBs) for defects. By implementing automation direct methodologies, these AOI systems can analyze components with high precision at speeds unachievable by manual inspection, ultimately leading to reduced production downtime.

In the automotive sector, specialized dynamometers serve as another example of custom testing equipment that enhances productivity through automation solutions. These devices assess vehicle performance under various conditions, allowing manufacturers to conduct necessary adjustments before releasing vehicles to the market. This not only ensures compliance with safety regulations but also boosts overall customer satisfaction by delivering reliable products.

Moreover, the integration of advanced sensor technologies into custom testing equipment has significantly improved data collection and analysis capabilities. By harnessing the power of automation solutions Emerson advocates, manufacturers can collect real-time data during the testing process, facilitating timely decision-making and continuous improvement in their operational practices.

In conclusion, the investment in custom testing equipment represents a strategic move for manufacturers seeking to uphold quality standards while enhancing efficiency. With the ongoing advancements in industrial automation solutions, businesses can leverage these innovative tools to remain competitive in their respective industries.

Integration of Automation Systems

The integration of Automation Systems is a crucial aspect of modern industrial processes. In today’s rapidly evolving market, organizations are increasingly turning to automation solutions to enhance efficiency and productivity. However, the successful integration of these systems within existing workflows presents a range of challenges that must be addressed comprehensively. Companies often grapple with compatibility issues, scalability concerns, and resistance to change from employees who may be hesitant to adopt new technologies.

One of the primary challenges in the integration process is ensuring that automation solutions can seamlessly interface with legacy systems. Many industries still rely on older technologies, which can create barriers when attempting to implement new automation direct systems. It is essential to choose automation solutions that are designed with interoperability in mind, allowing for smooth communication between new and existing equipment. This approach not only reduces operational disruptions but also maximizes the return on investment in automation technologies.

To navigate these complexities, organizations can adopt best practices for successful integration. Thorough planning is paramount; before implementation, companies should conduct a comprehensive analysis of their current processes, identifying areas where automation can deliver the most significant impact. Engaging key stakeholders early in the process is equally important, as it fosters buy-in and can help alleviate fears about job displacement. Collaboration with experienced vendors who offer support and guidance throughout the integration process can also play a pivotal role in overcoming obstacles.

Moreover, ongoing training and education should be prioritized to equip employees with the necessary skills to work effectively alongside automated systems. By focusing on creating a culture that embraces innovation, organizations positioned themselves to reap the benefits of automotive automation solutions and industrial automation solutions alike. In conclusion, a strategic approach to the integration of automation systems paves the way for enhanced operational efficiency and sustainability.

Applications of Automation Across Industries

Automation technology is revolutionizing a myriad of industries by enhancing operational efficiency, reducing human error, and optimizing resource management. One of the most prominent sectors benefiting from automation is manufacturing. Here, automation direct implementations such as robotics and advanced machinery have streamlined production lines, reduced cycle times, and improved product quality. The adoption of industrial automation solutions enables manufacturers to manage complex processes more effectively, resulting in increased throughput and lower operational costs.

Another significant area where automation solutions have made a profound impact is healthcare. Automation finds applications in patient management systems, robotic surgeries, and telehealth services. With the advent of automation solutions Emerson and other technology providers have developed, healthcare facilities can automate administrative tasks, such as scheduling and billing, allowing medical professionals to focus more on patient care. Furthermore, real-time patient monitoring devices contribute to improved outcomes by facilitating timely interventions and enhancing data accuracy.

In the financial sector, automation is redefining transactional processes and risk management. Automated systems facilitate faster processing of payments, fraud detection, and regulatory compliance. Financial institutions leveraging automotive automation solutions can respond to market fluctuations with increased agility. The process of automation solutions, such as algorithmic trading and AI-driven analytics, enables these institutions to operate with minimum human intervention, thus maintaining efficiency and accuracy.

Lastly, the logistics industry is experiencing significant transformations due to automation technologies. Automated warehouses, inventory management systems, and delivery drones are examples of how this sector is optimizing supply chain efficiency. By incorporating industrial automation solutions, logistics companies can enhance tracking capabilities and streamline operations, ultimately leading to reduced delivery times and improved customer satisfaction. The breadth of automation spans diverse industries, showcasing its essential role in driving modern operational practices.

Boosting Efficiency with Ming Automation Technology

At Ming AutoTek, we pride ourselves on our expertise in delivering custom automation solutions that enhance productivity in the automotive industry. Our commitment to quality and innovation sets us apart as a leader in industrial automation. Whether you need custom automation welding equipment or advanced testing systems, we have the expertise to help you achieve your manufacturing goals.

By embracing automation technologies, businesses can not only improve their operational efficiency but also stay competitive in a rapidly evolving market. Let Ming AutoTek be your partner in transforming your manufacturing processes through tailored automation solutions.

Conclusion: The Future of Automation Solutions

The automation landscape is evolving at a remarkable pace, fueled by technological advancements and growing demand for efficiency across industries. As businesses strive to optimize operations, automation has become more crucial than ever. This trend is reshaping not just traditional manufacturing but also industries like automotive and logistics, where precision and speed are key. The benefits of industrial automation—streamlining processes, reducing errors, and cutting costs—are undeniable.

Looking ahead, the integration of artificial intelligence and machine learning will drive even smarter, more adaptive systems. This will lead to enhanced decision-making, allowing automation to respond dynamically to ever-changing operational needs. The future promises unprecedented levels of efficiency and productivity as these technologies work hand-in-hand. Moreover, industries will continue exploring tailored automation solutions that address specific challenges, boosting competitiveness in a global market.

Companies embracing this shift, particularly by partnering with leading providers like Emerson, will position themselves for substantial growth. Automation isn’t just about replacing manual tasks—it’s about unlocking transformative potential, allowing businesses to focus on strategic priorities rather than routine operations. By integrating automation into their workflows, organizations can stay ahead of industry changes and ensure long-term success.